Categories

Contact Us

Unit 404, Unit B, Building 14, Enterprise One, No. 68 Luotang Road, Xingsha Economic Development Zone, Changsha, Hunan

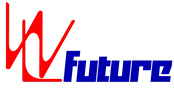

LED Light Fiber Optic Jumpsuits

Brand Name: Future

Clothing material: Uniform

Style Model: WL-02

Lighting color: RGB

Operating voltage: DC5V

Clothing size: customized

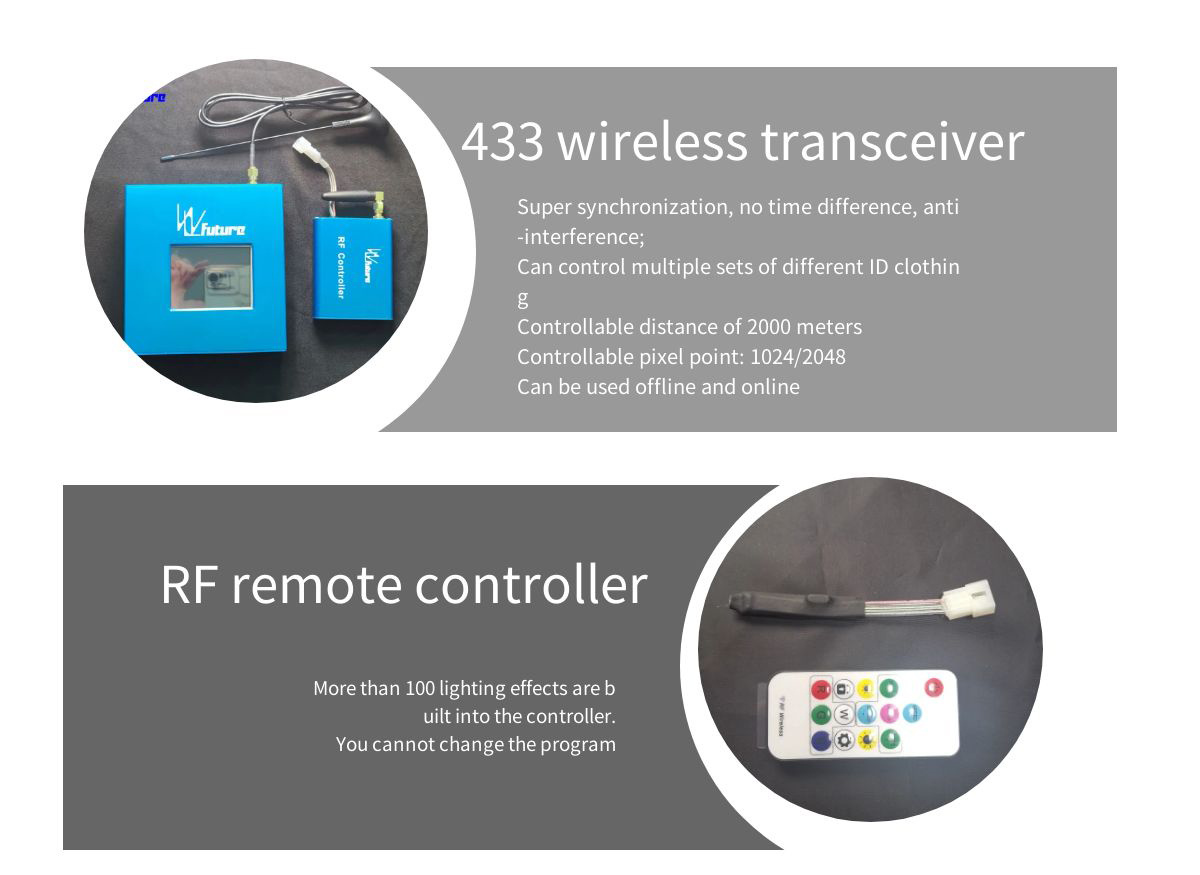

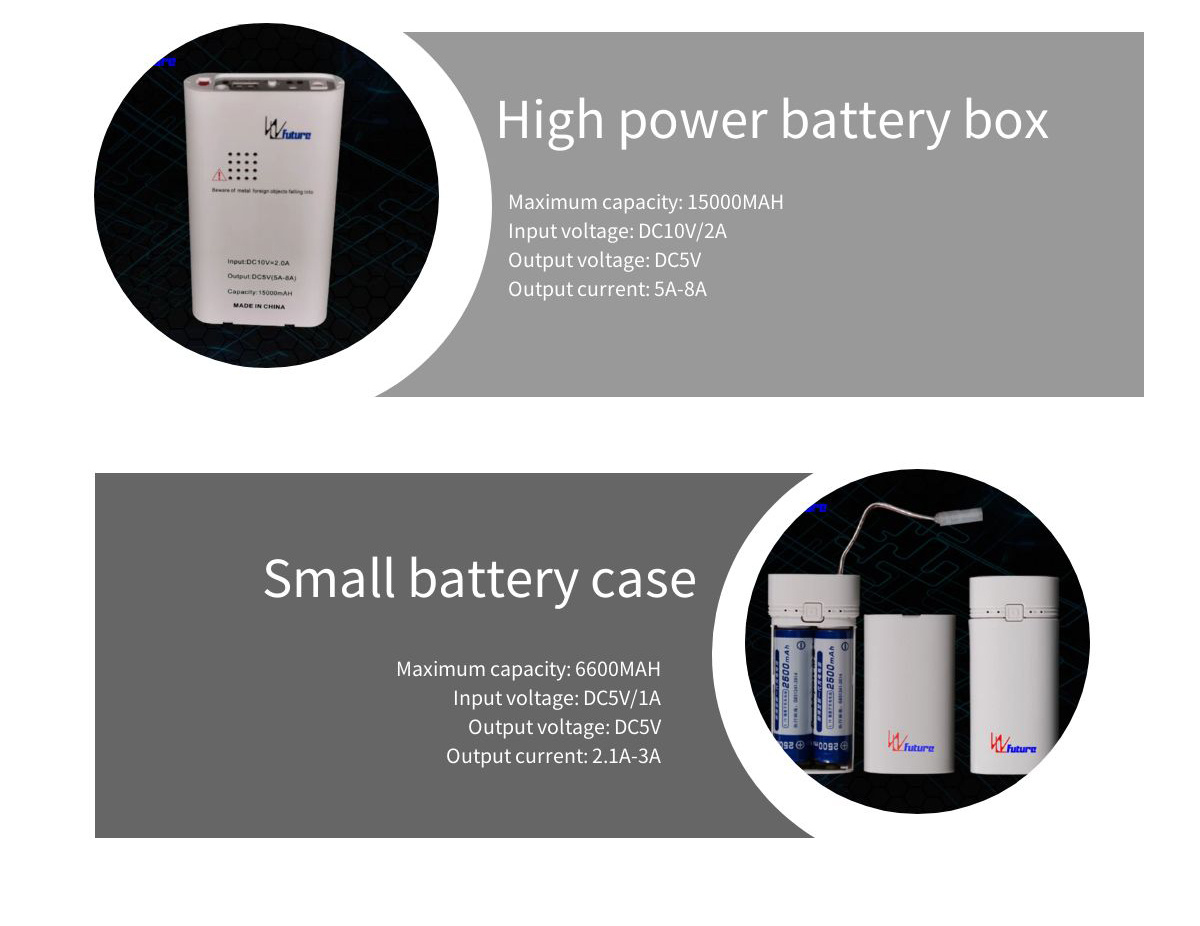

Battery model: WL- P09/WL-P10

keyword:

Luminous clothing

Classification:

Optical Fiber Luminous Garment

LED Light Fiber Optic Jumpsuits

Product Information

Clothing Accessories

Remark: Contact us and we will advise you!

Advantages

Software Supply

The software is Hunan Future Creative Technology Co., Ltd exclusively develop for luminous costumes, it is very simple and easy to understand & operate and the important is the synchronous speed is very accurate,it can edit hundreds sets of different types of luminous costumes at once, also can insert music and costumes at the same time in the simulation mode very clear editing program on costumes effects what you want.

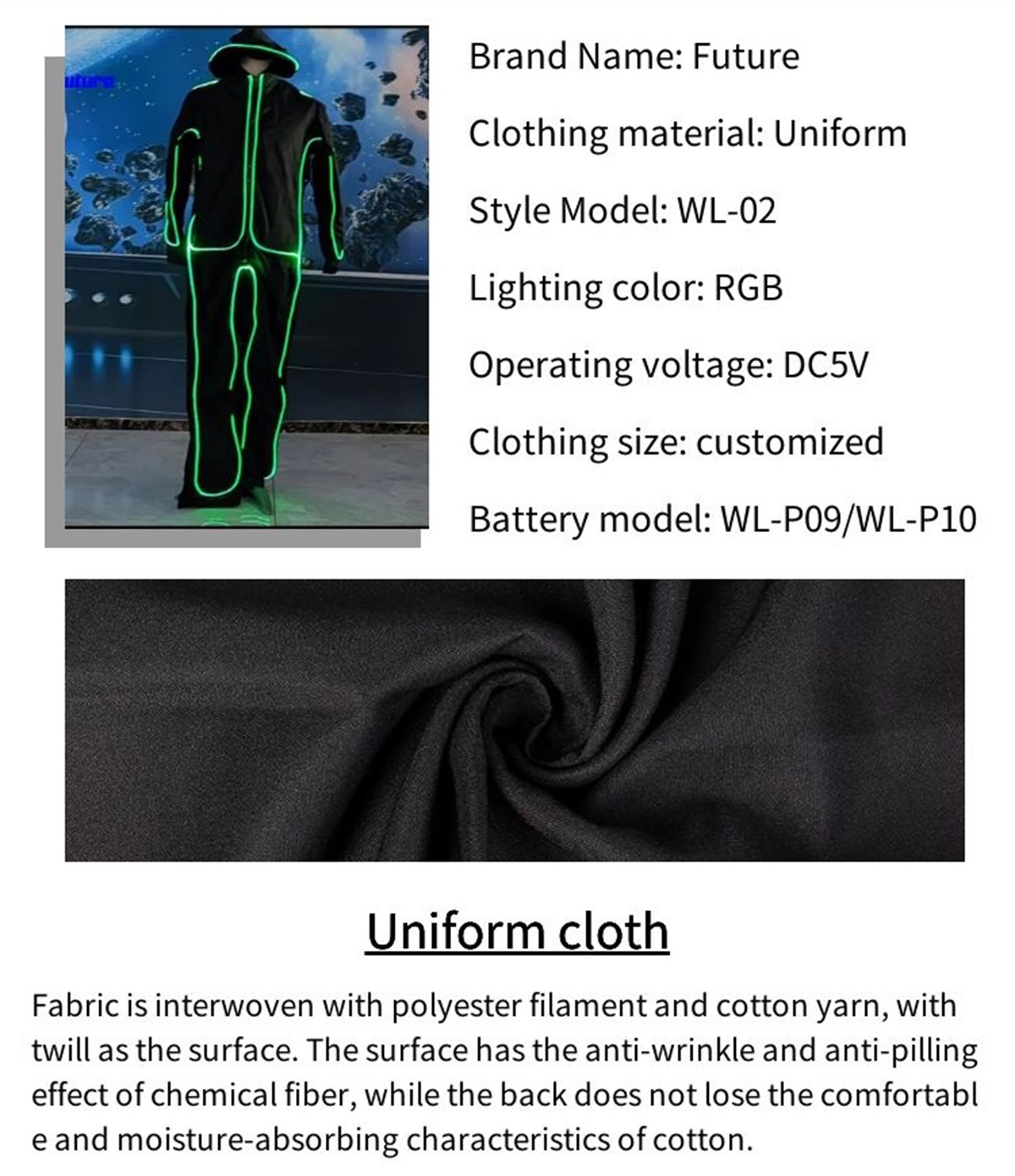

LED Light Fiber Optic Jumpsuits supports 3 types of controllers:

(a)Ordinary SD card controller

(b)433 wireless synchronous controller

(c) 2.4G wireless synchronous controller

Personalized programming, make your performance with led light fiber optic jumpsuits more colorful and wonderful!

Company Profile

Hunan Future Creative Technology Co., Ltd. is a leading manufacturer of LED luminous clothing,LED Light Fiber Optic Jumpsuits optical fiber clothing and LED luminous props, which has obtained national patents. Our program engineers and costume designers have been in this field for over 10 years and have unparalleled and very extensive experience. And has experienced sales manager, to provide you with quality pre - sales, after-sales service.

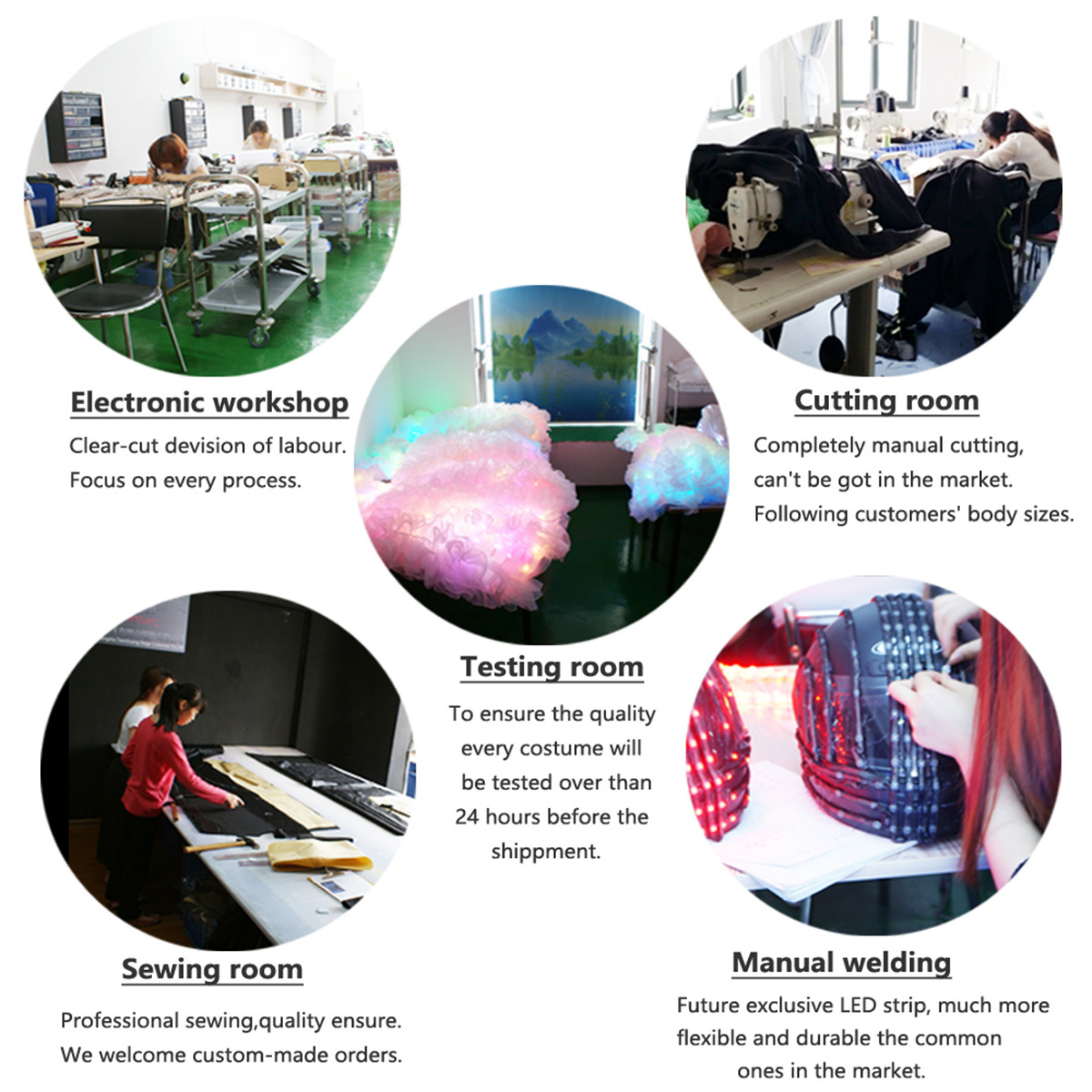

The strict requirements of each process bring better product presentation!

Extended reading:

Optical fiber fabric, also known as optical fiber cloth, luminous cloth, LED luminous fabric, luminous cloth, is a kind of plastic fiber as the warp or weft, through the warp and weft staggered and composed of a special woven fabric. How is this fabric made?

I. Preparation before weaving:

1. Textile engineers shall produce a production process sheet according to the production process requirements. One or more of the raw materials used in the process sheet must be plastic fiber, and the specification is generally 0.25MM or 0.5MM.

2. The warp shaft is made by the workers according to the single process. The warp shaft of the fiber fabric has the biggest difference from that of the ordinary fabric.

3. After the warp shaft is pulled, the machine starts to load. The machine for weaving fiber fabric is generally rapier loom.

Ii. Matters needing attention in weaving work:

1, the machine to complete the start of trial, in the process of trial need to be adjusted according to different problems, which requires the machine repair workers to pay hard labor experience and wisdom

2. After the machine is adjusted properly, the workers can produce and weave in bulk. Here we need to pay attention to the weaving process must be strictly clean, because the fiber fabric is yarn-dyed, do not need to finish.

3, when the workers weave fiber fabric to a certain amount, it is necessary to remove the fabric from the scroll of the machine, and then the quality inspection workers.

3. Storage after weaving: after the fiber fabric is woven, it shall be checked by quality inspectors and then packed in packaging bags by packing workers in the warehouse. Generally, it is packed in three-layer packaging bags, which shall be waterproof, moisture-proof and sun-proof.

Previous

Our History

这里是占位文字

Luminous Braided Strapless Skirt

这里是占位文字

Advisory Message

To: Hunan Future Creative Technology Co., LTD